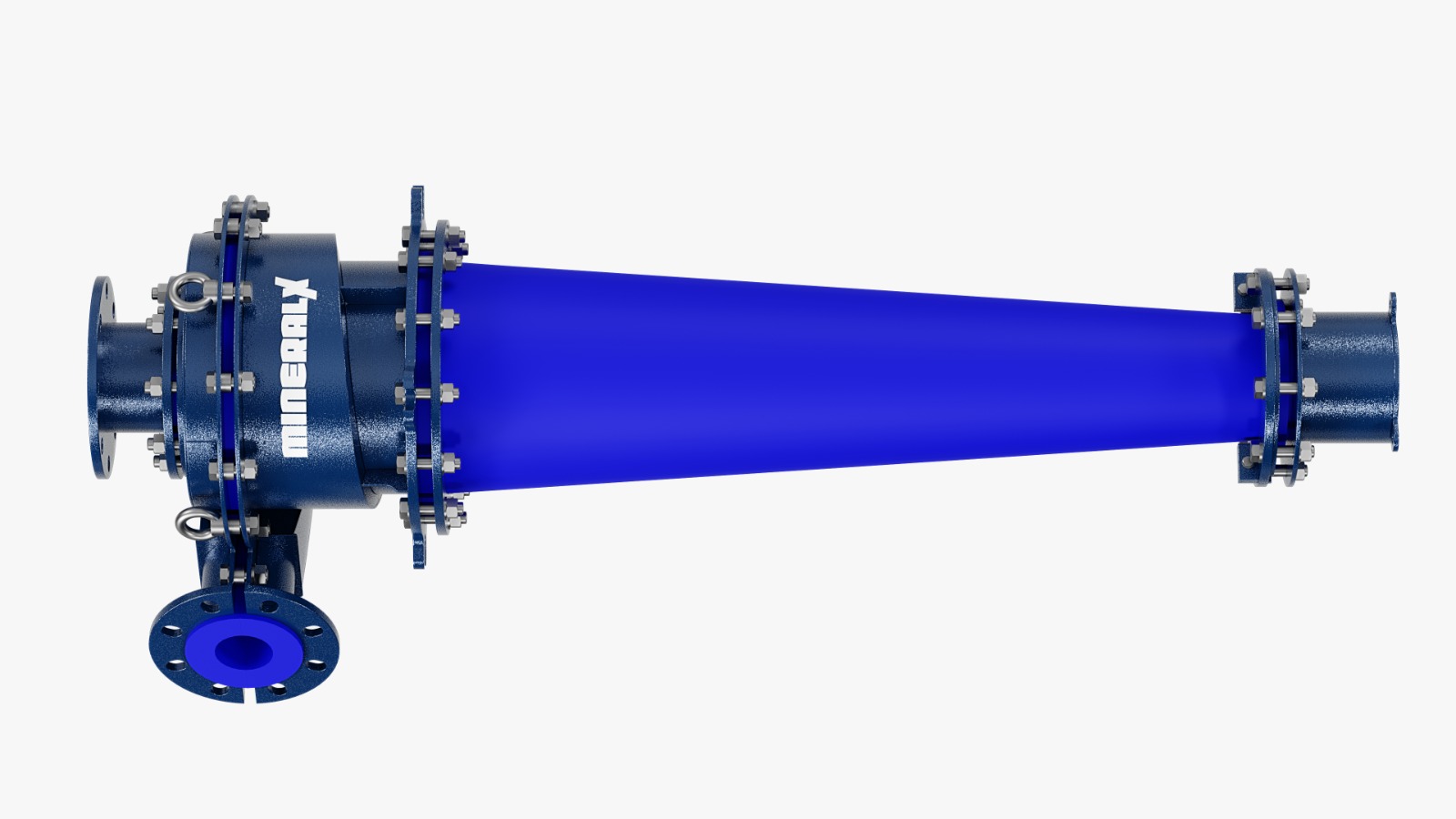

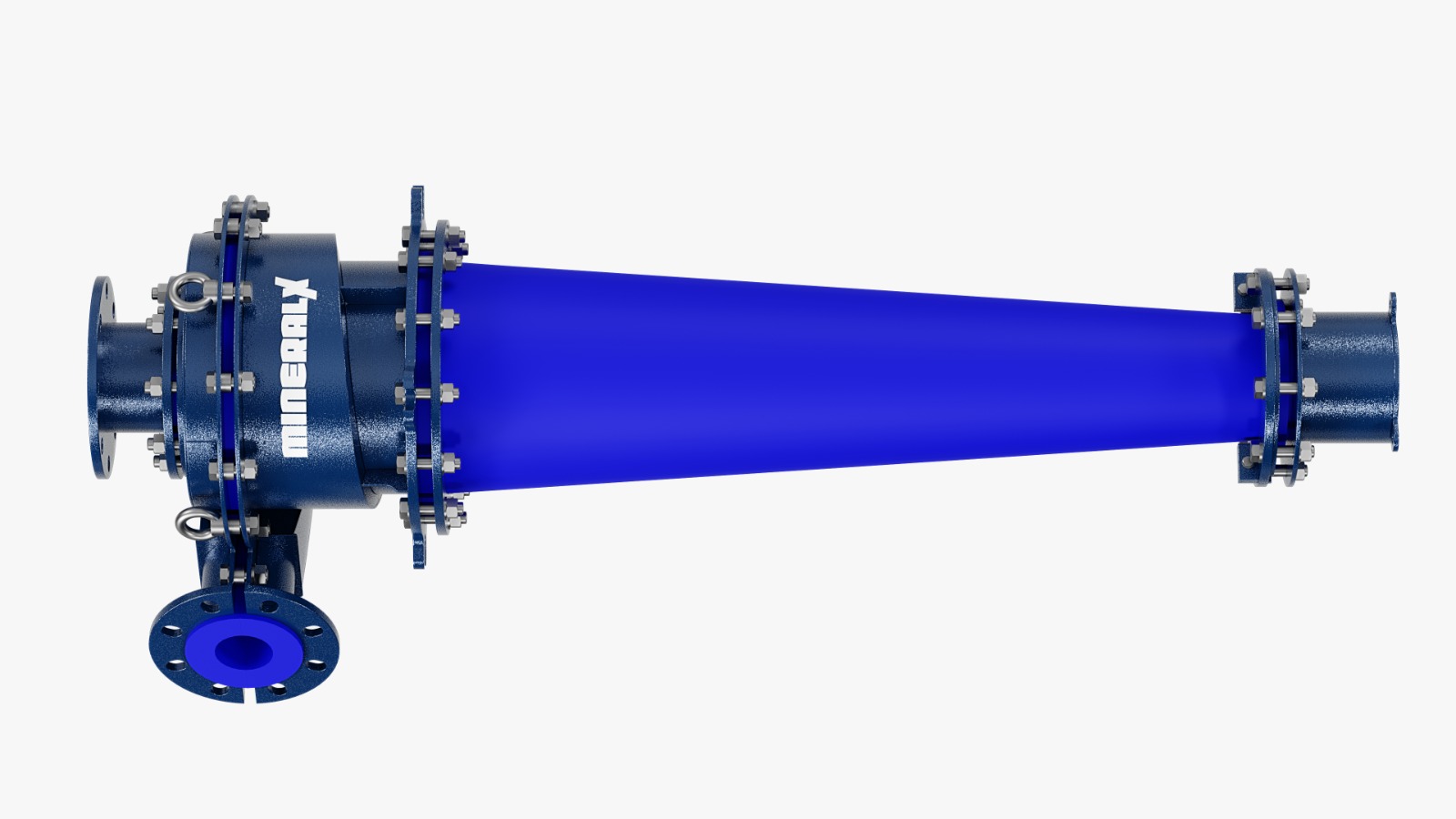

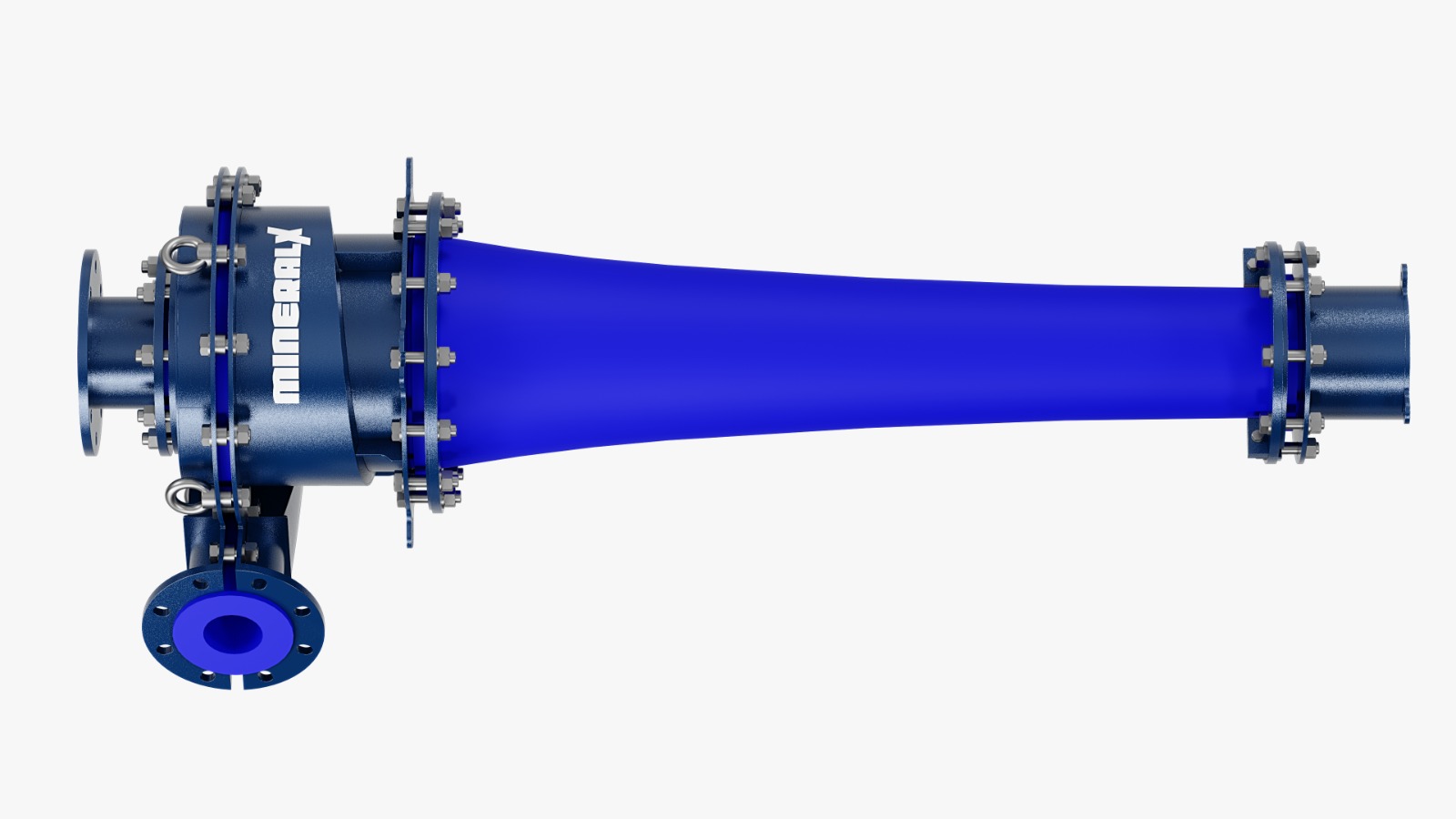

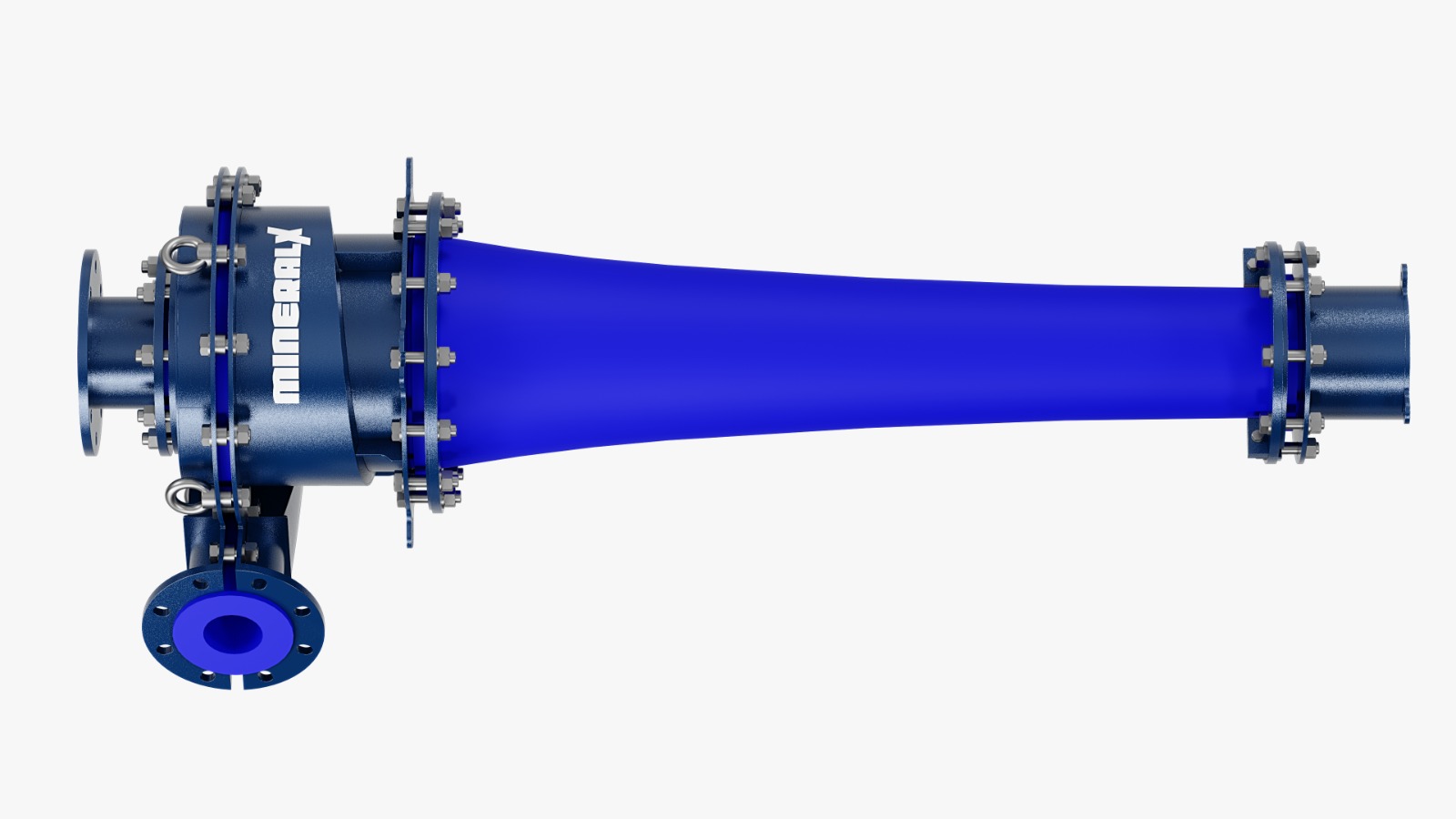

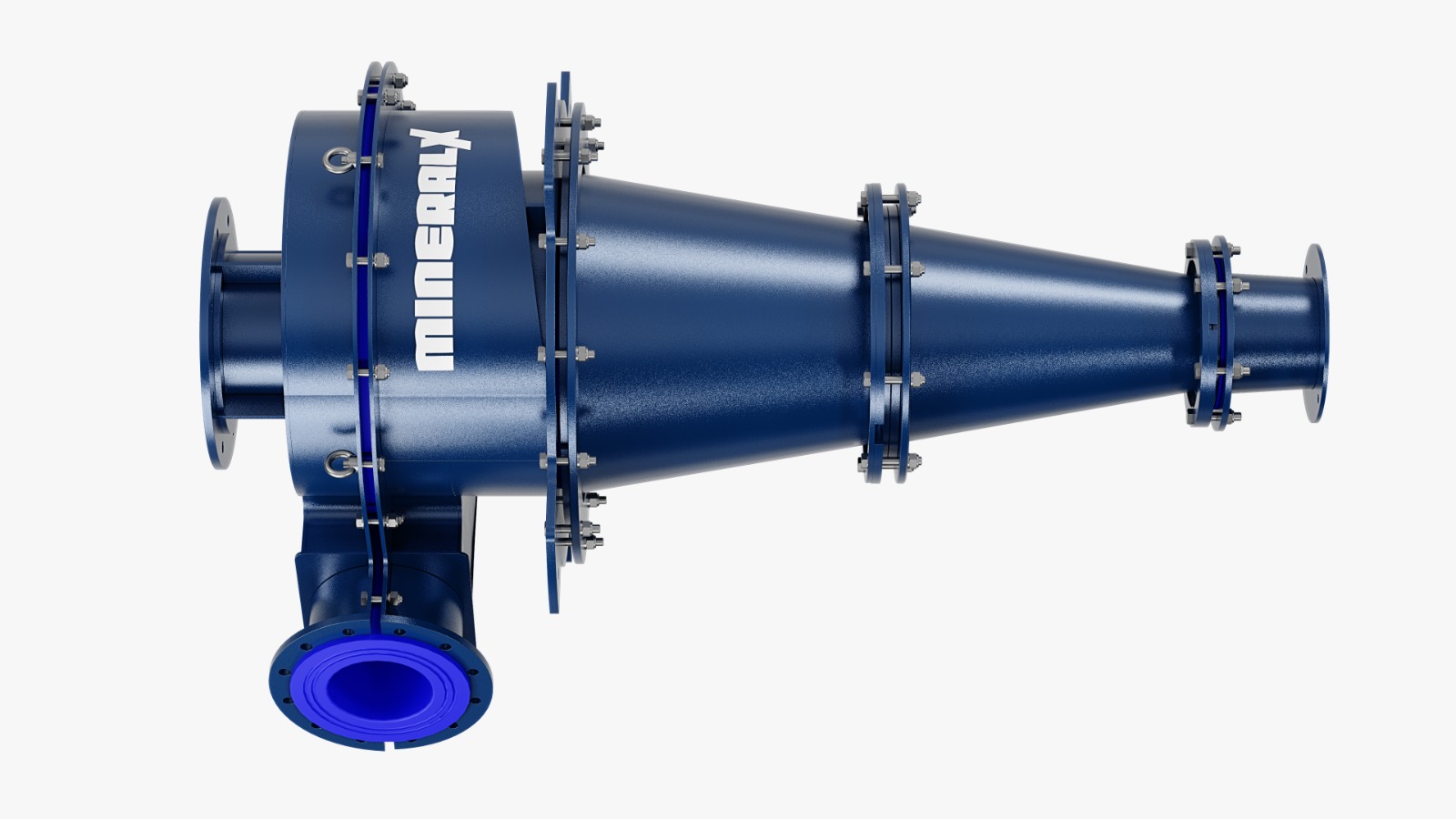

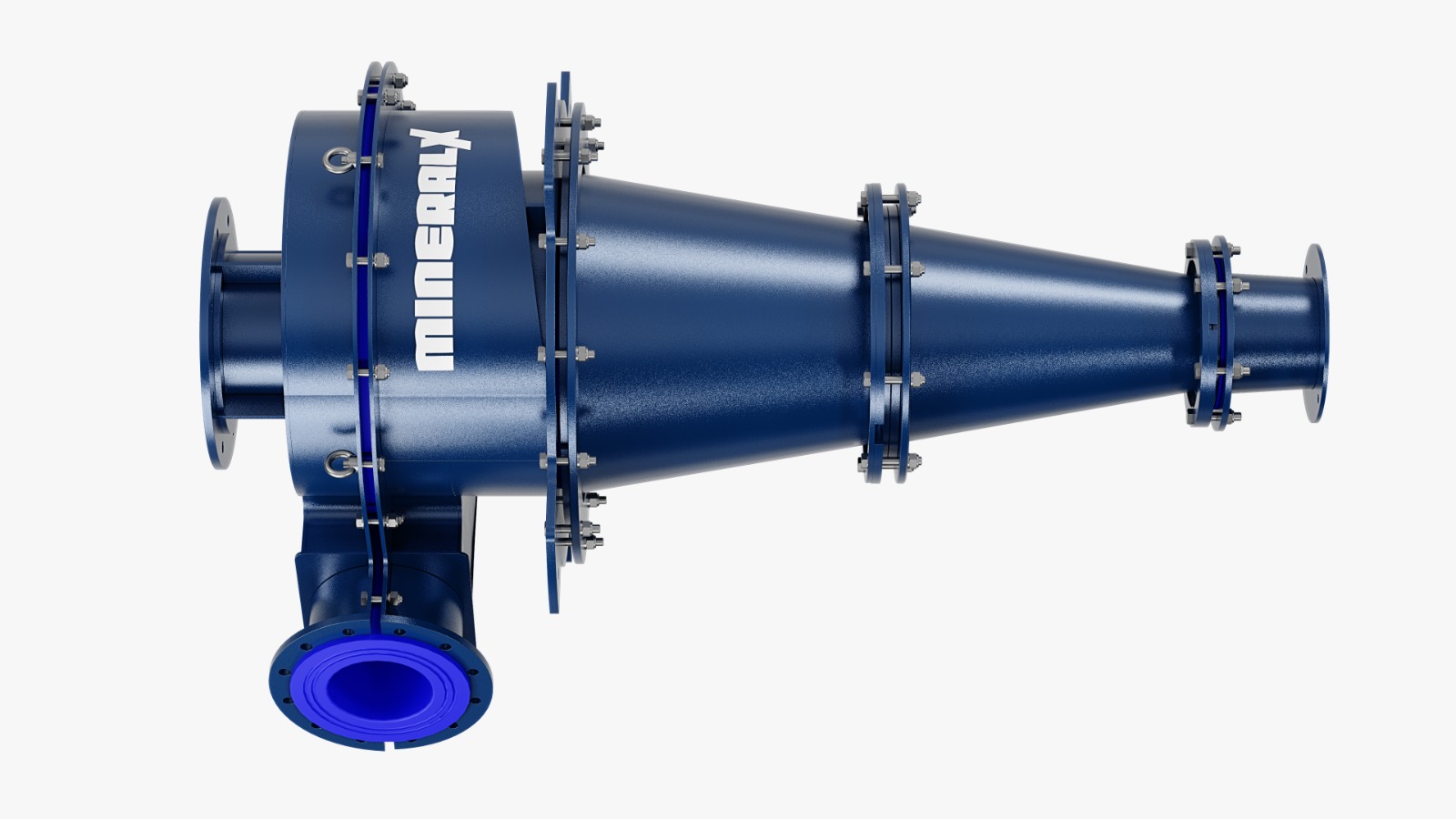

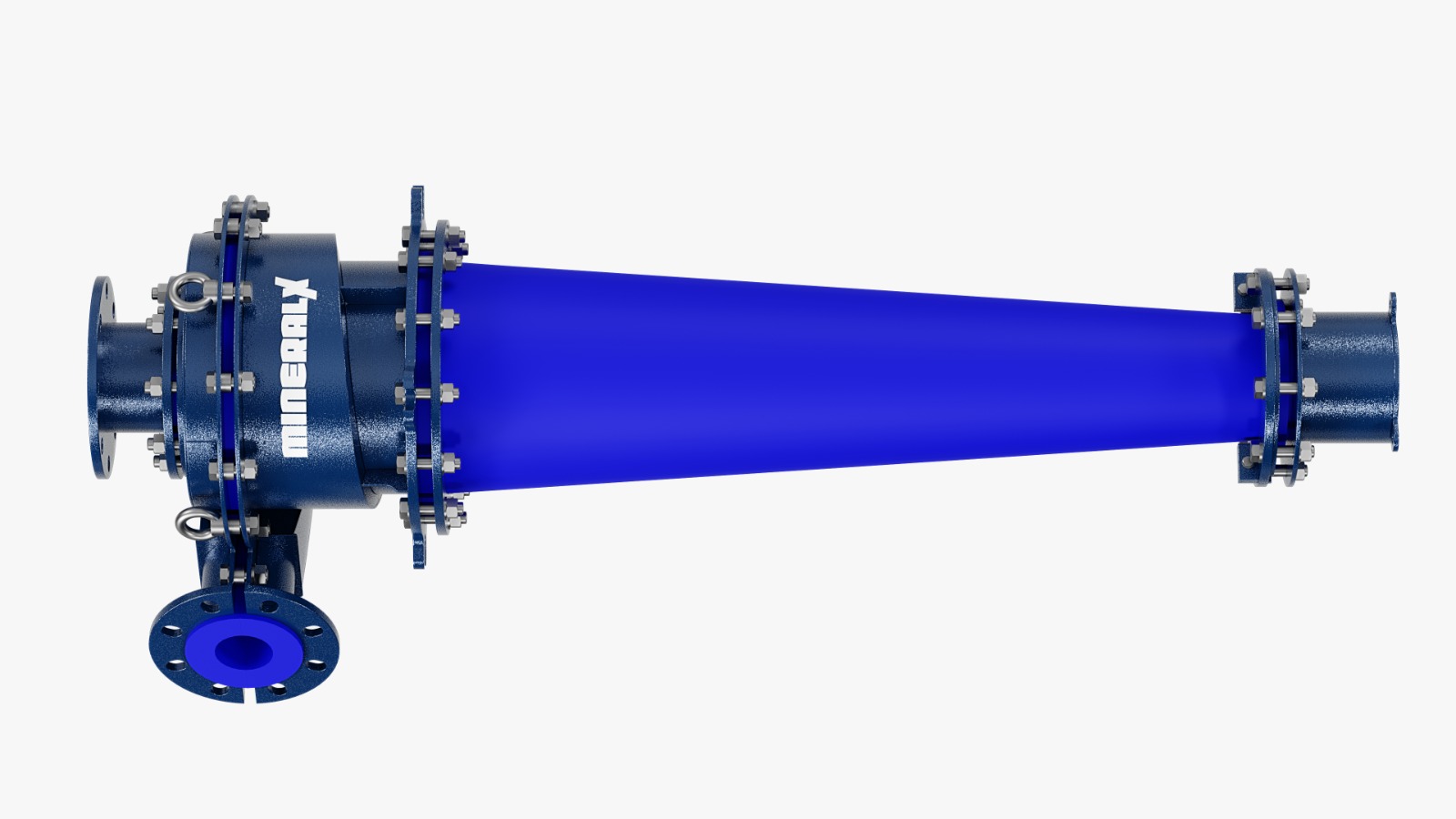

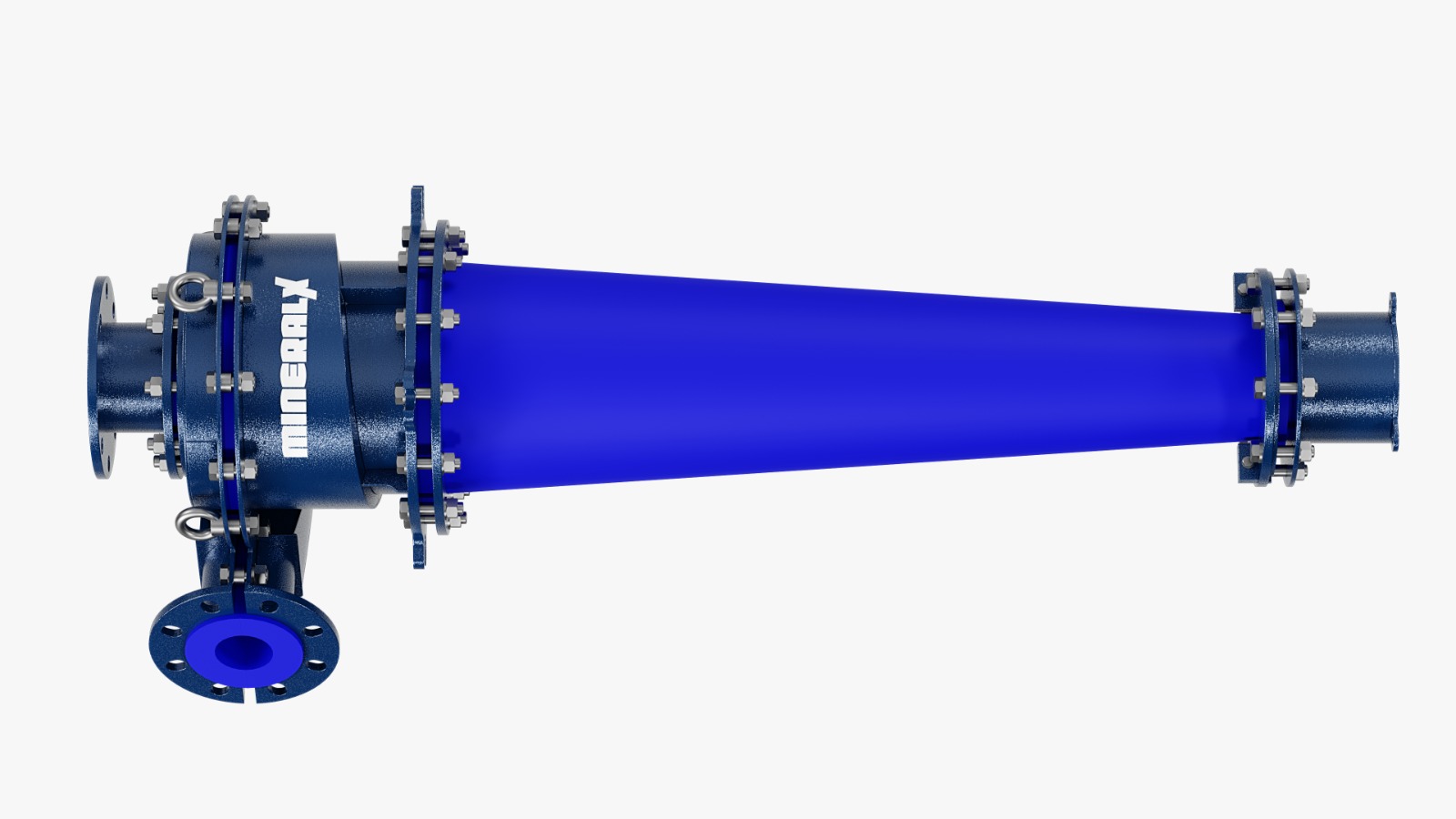

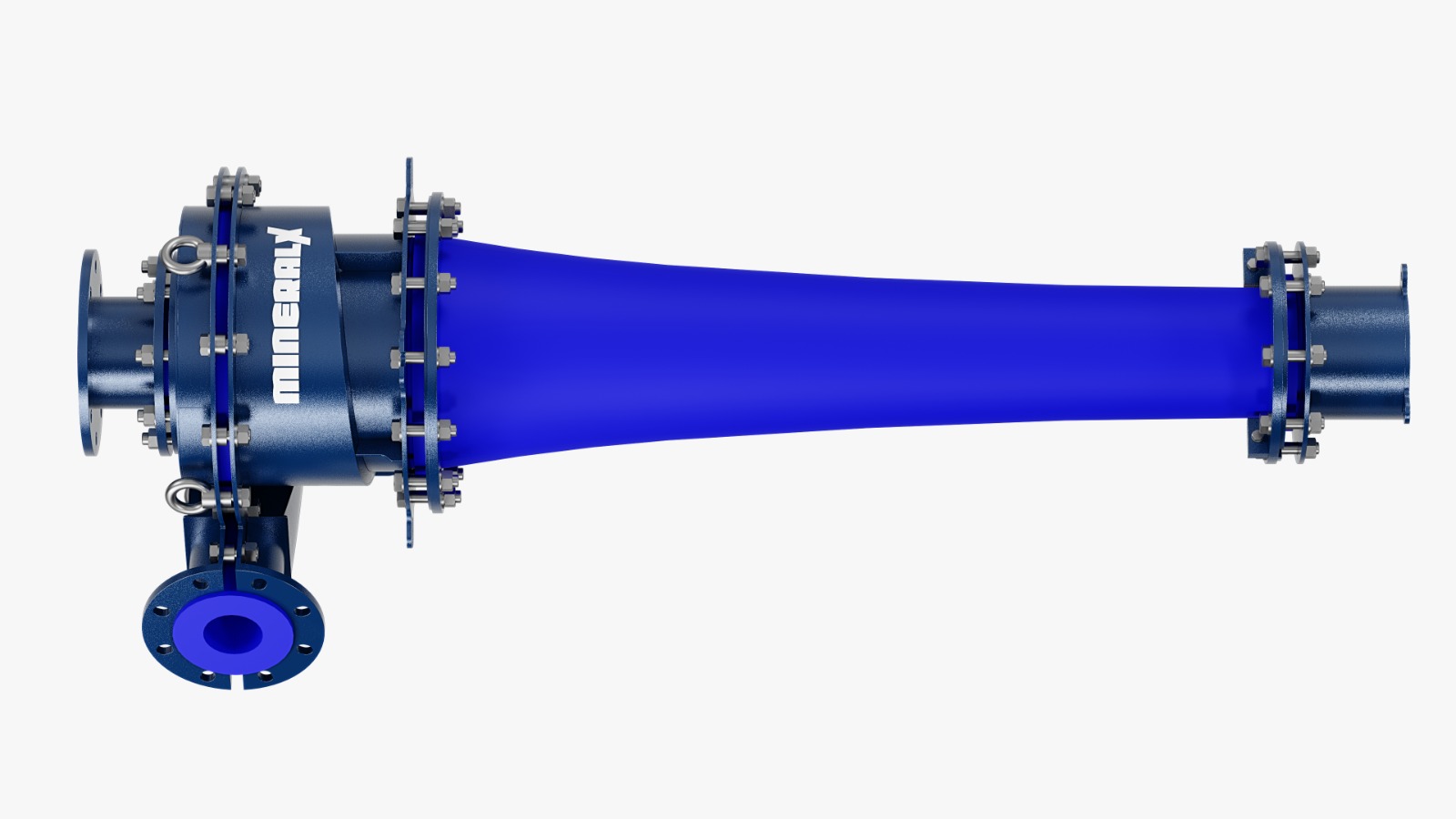

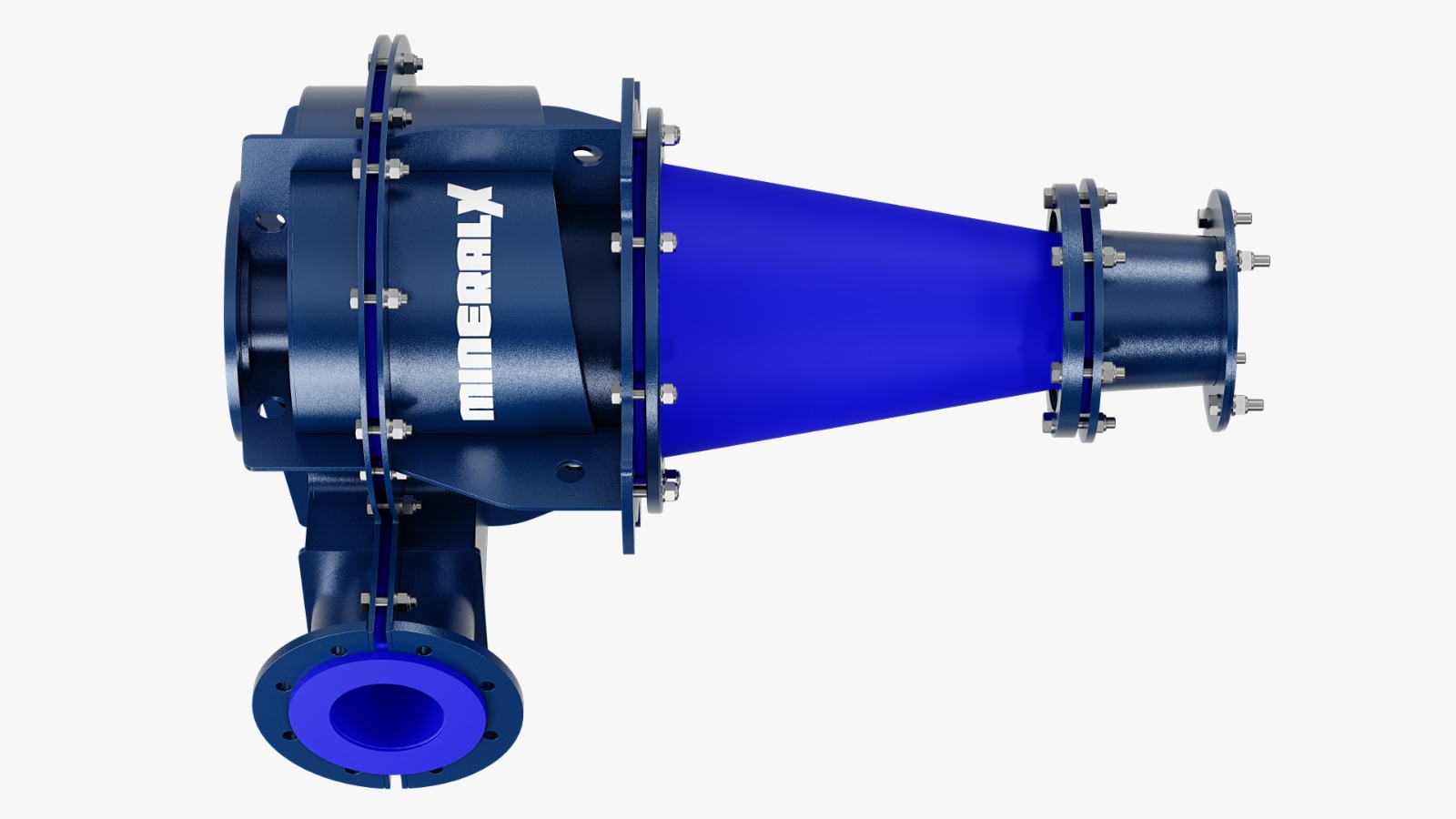

At Mineralx Flowtech, our Solid–Liquid Classification Hydrocyclones are engineered to deliver efficient and reliable separation of solids from liquid suspensions based on particle size. These systems are essential for achieving precise slurry classification and maintaining process consistency across a range of mineral and industrial applications.

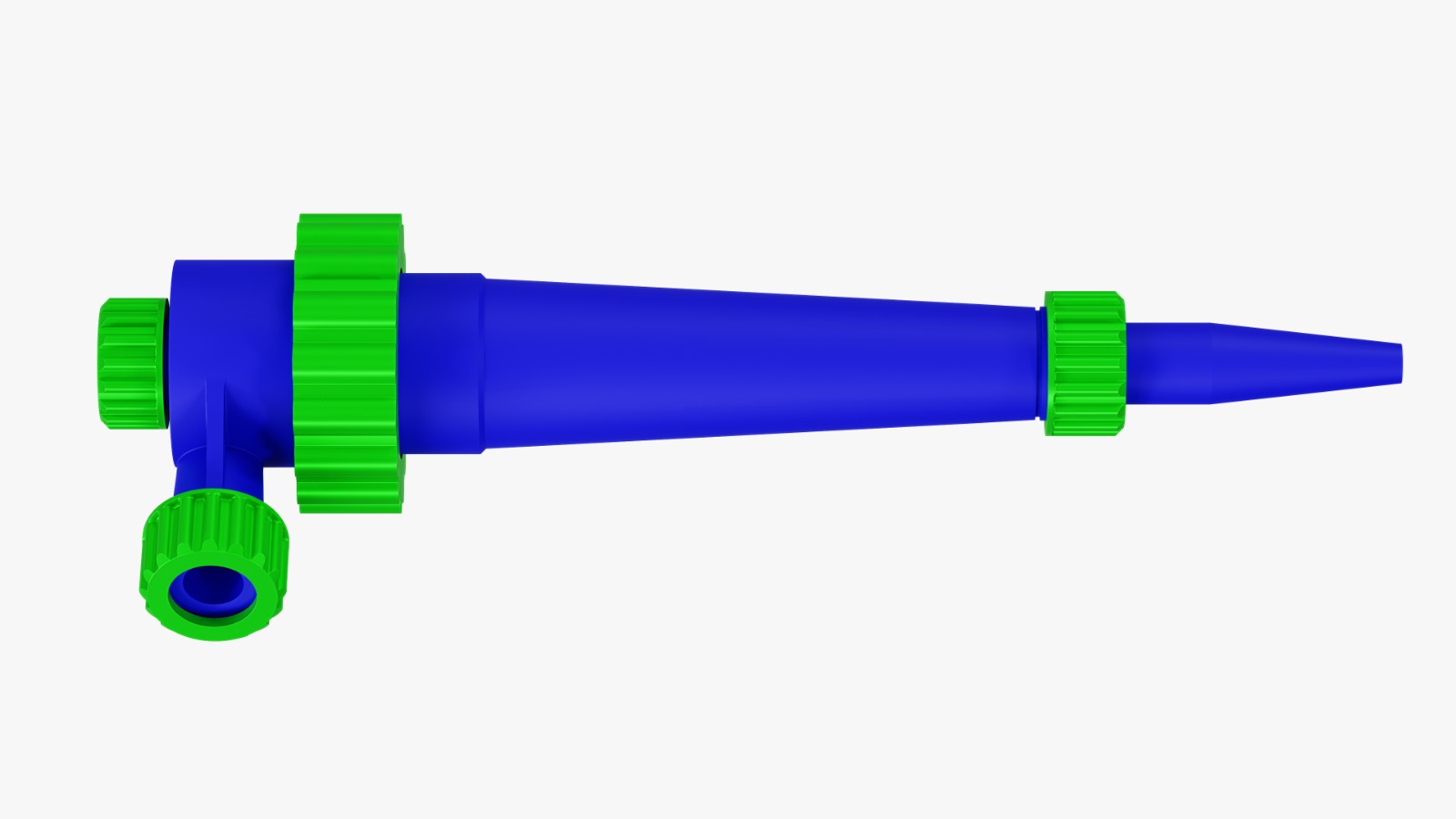

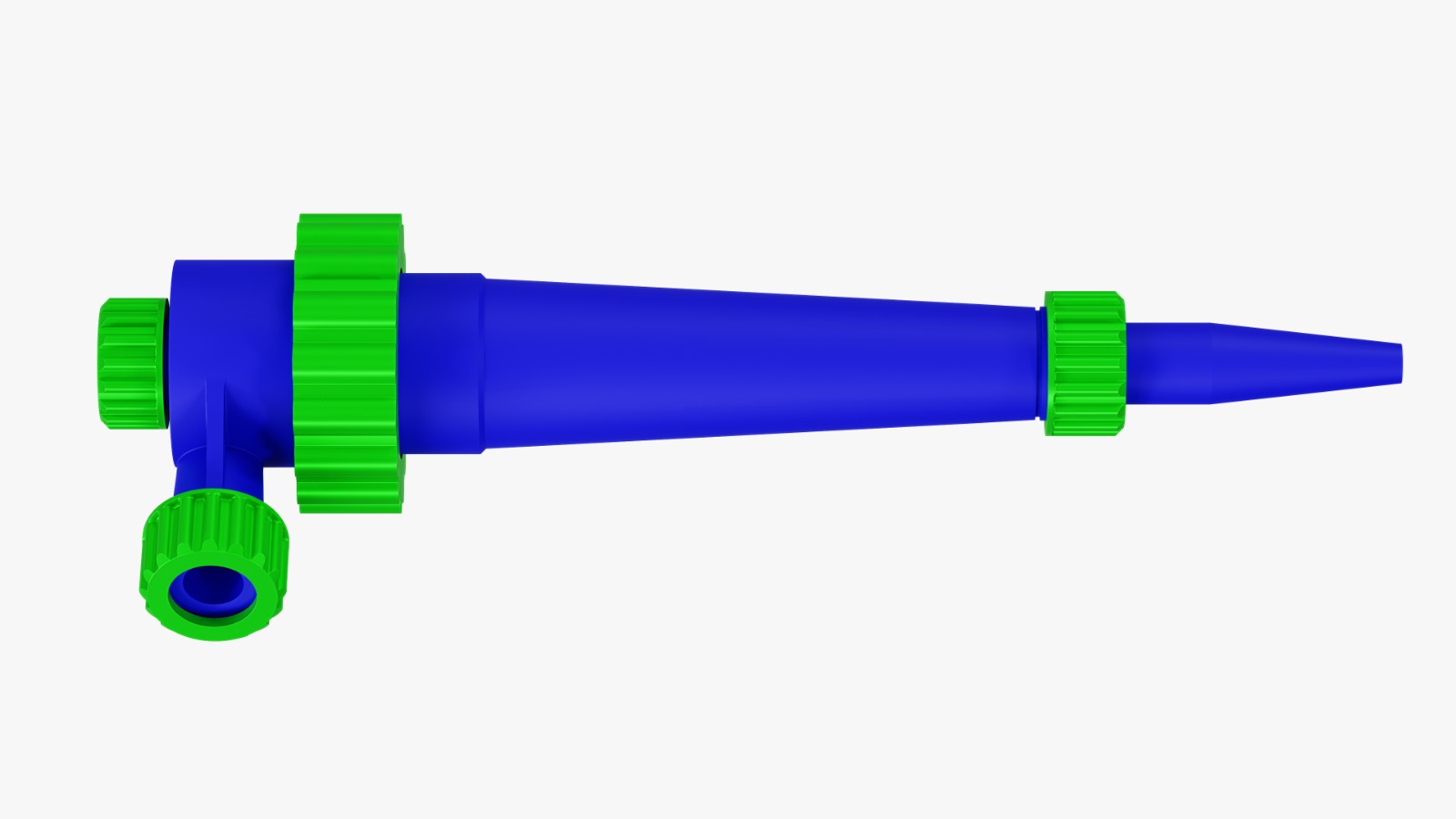

We offer two types of hydrocyclones to suit specific classification needs. Our Fine Classification Hydrocyclones are designed for the accurate separation of ultra-fine particles, offering sharp cut-point control, improved fines recovery, and reduced bypass. These units are ideal for processes where narrow particle size distribution is critical to performance.

For coarser separation tasks, our Coarse Classification Hydrocyclones are optimized to remove oversized particles from slurry streams. This ensures stable classification, protects downstream equipment, and enhances overall system efficiency.

Available in various sizes and materials, including high-wear-resistant options, Mineralx Classification Hydrocyclones are built for long service life, dependable operation, and seamless integration into grinding, desliming, and dewatering circuits.

A compact, precision-engineered unit ideal for pilot-scale and low-capacity applications requiring fine particle separation and consistent overflow clarity.

➤ Feed: 4 – 25 m³/hr

➤ Pressure: 35 – 280 kPa

A space-efficient classifier designed for light-duty mineral and sand classification processes, offering reliable performance in smaller grinding circuits or dewatering systems.

➤ Feed: 11 – 52 m³/hr

➤ Pressure: 35 – 240 kPa

A high-efficiency classifier built for moderate-capacity separation tasks, engineered to handle coarse and fine particles in mill discharge, ore dressing, and aggregate systems.

➤ Feed: 31 – 147 m³/hr

➤ Pressure: 35 – 200 kPa

A rugged, heavy-duty unit designed for high-throughput mineral classification, offering improved operational stability and reduced maintenance in demanding processing environments.

➤ Feed: 60 – 140 m³/hr

➤ Pressure: 35 – 180 kPa

A large-capacity industrial classifier optimized for large-scale beneficiation and dewatering processes, providing enhanced settling performance and robust structural reliability under continuous load.

➤ Feed: 125 – 225 m³/hr

➤ Pressure: 35 – 180 kPa

A large-capacity hydrocyclone with an enlarged vortex finder for sharper separation, higher efficiency, and reliable performance in continuous beneficiation and dewatering operations.

➤ Feed: 220 – 425 m³/hr

➤ Pressure: 35 – 155 kPa

Ultra-compact hydrocyclone ideal for lab-scale testing and precision classification in pilot systems handling ultra-fine particles.

➤ Feed: 0.2 - 0.3 m³/hr

➤ Pressure: 60 - 207 kPa

Compact unit designed for low-capacity circuits requiring sharp cut-point control and fine particle recovery in light-duty mineral processes.

➤ Feed: 1.7 - 5.5 m³/hr

➤ Pressure: 60 - 207 kPa

Small-scale classifier suitable for fine classification in limited-space applications such as small desliming systems or secondary grinding circuits.

➤ Feed: 4.5 - 13.6 m³/hr

➤ Pressure: 60 - 207 kPa

Mid-capacity hydrocyclone offering efficient fine particle separation with consistent overflow clarity in compact processing lines.

➤ Feed: 4 - 25 m³/hr

➤ Pressure: 35 - 280 kPa

Versatile unit for fine classification in medium-duty applications including grinding circuit overflow control and desliming operations.

➤ Feed: 11 - 52 m³/hr

➤ Pressure: 35 - 240 kPa

High-efficiency classifier engineered for large-scale mineral plants, offering enhanced fines recovery and reduced bypass under continuous operation.

➤ Feed: 31 - 147 m³/hr

➤ Pressure: 35 - 200 kPa